Instead of collecting rays, panels from the Fighting Jays Solar Farm in Guy were hammered by hail. SkyDrone13 captured thousands of rows of shattered panels - damage more concerning to Kaminski than what happened to his home.

Experts said that most of the time, large solar farm panels are made of compound cadmium telluride.

This is something Kaminski is worried about because he uses well water.

"That's what we take a shower with, we drink with," Kaminski explained. "It could be in our water now."

Experts said that cadmium telluride panels are cheaper and tend to be found on large solar farms. ABC13 went inside the office space at Fighting Jays Solar to ask what's in the solar panels.

An employee told Eyewitness to email. ABC13 did and asked questions, including whether the compound cadmium telluride was in the equipment.

A spokesperson called ABC13 but wouldn't answer questions on the record. The solar farm's website doesn't mention anything about chemicals in the solar panels but states that insurance policies will cover a hailstorm if it hits.

According to the Environmental Protection Agency, cadmium telluride is found in some solar panels. It is a toxic substance that can cause kidney, heart, skin, and lung issues.

Ramesh said even if the dangerous chemical leaked, it was a very small amount and would need a long time to enter the water supply.

In the meantime, huge sums of taxpayers’ money are given in grants, spent installing and replacing these systems - they call it magical “free money”…

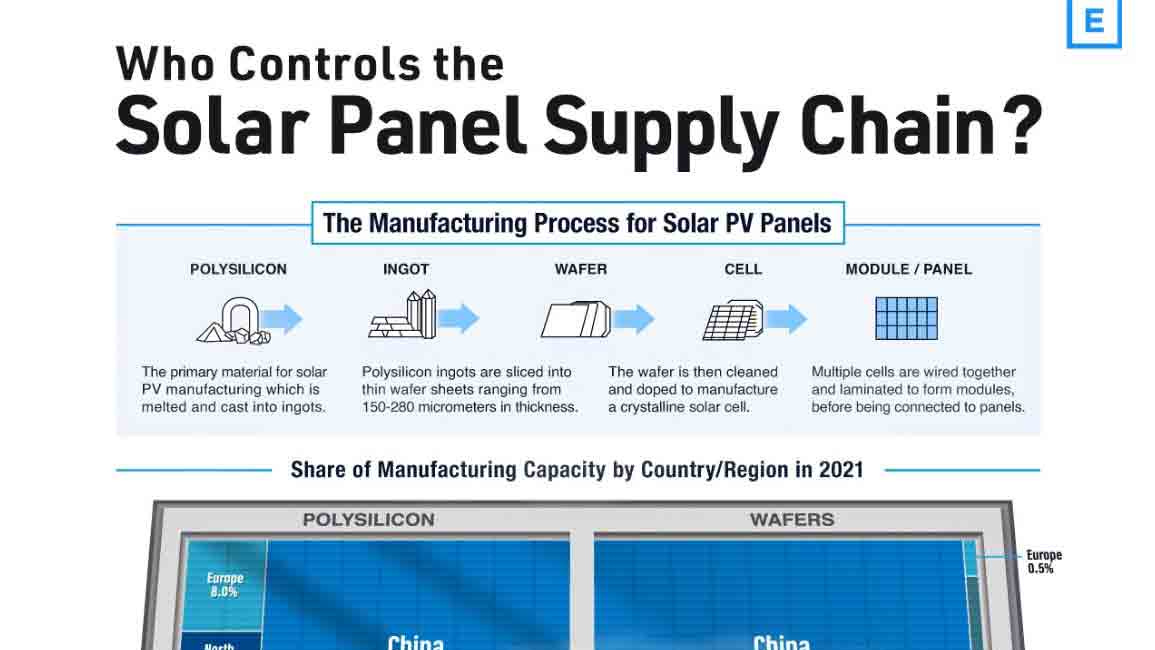

…most of which goes to China where they use energy from high-polluting coal to make the panels.

Manufacturing crystalline silicon solar PV panels is an energy-intensive process. The amount of energy consumed globally to produce polysilicon, ingots and wafers, and cells and modules reached 364 PJ in 2021, roughly equivalent to Croatia’s total primary energy demand.

Coal fuels 62% of the electricity used for solar PV manufacturing, significantly more than its share in global power generation (36%), largely because production is concentrated in China – mainly in the provinces of Xinjiang and Jiangsu. In these provinces, coal often accounts for more than 75% of the power supply, partly because the government offers favourable tariffs.

Globally, CO2 emissions from solar PV manufacturing almost quadrupled to more than 51 900 kilotonnes of carbon dioxide (kt CO2) over the last decade, 2 accounting for almost 0.15% of total energy-related global emissions in 2021. This growth resulted from an almost sevenfold production increase in the last decade and from manufacturing capacity moving to China.

From beginning to end, this is a filthy scam (as I reported previously):

From the IEA:

Considering historical capacity additions, we estimate that the global cumulative flow of decommissioned solar PV capacity will reach around 7 GW by 2030 and could increase to over 200 GW by 2040. This represents 400-600 kt of embodied materials cumulatively by 2030 and 11-15 Mt by 2040. As setting up effective policy frameworks and value chains can take time, it is crucial that governments, industries and other stakeholders prepare now to manage the future surge of solar PV waste from a systemic, circular-economy perspective.

It seems a little late to be having this conversation. These panels have been going out to landfills for years.

Managing end-of-life (EoL) flows of solar PV equipment is an environmental challenge. In addition to contradicting circularity principles, putting PV panels in landfills can cause environmental pollution and health issues due to the presence of hazardous materials such as lead.

However, existing PV recycling processes are encountering economic challenges. Current recycling technologies for c-Si modules struggle to generate enough revenue from the recovered materials to cover the cost of the recycling process.

You would think that since solar PV is a key part of the Green Agenda, the technology would not be promoted until all the recycling was factored into the equation. However, like the wind generators, it was not:

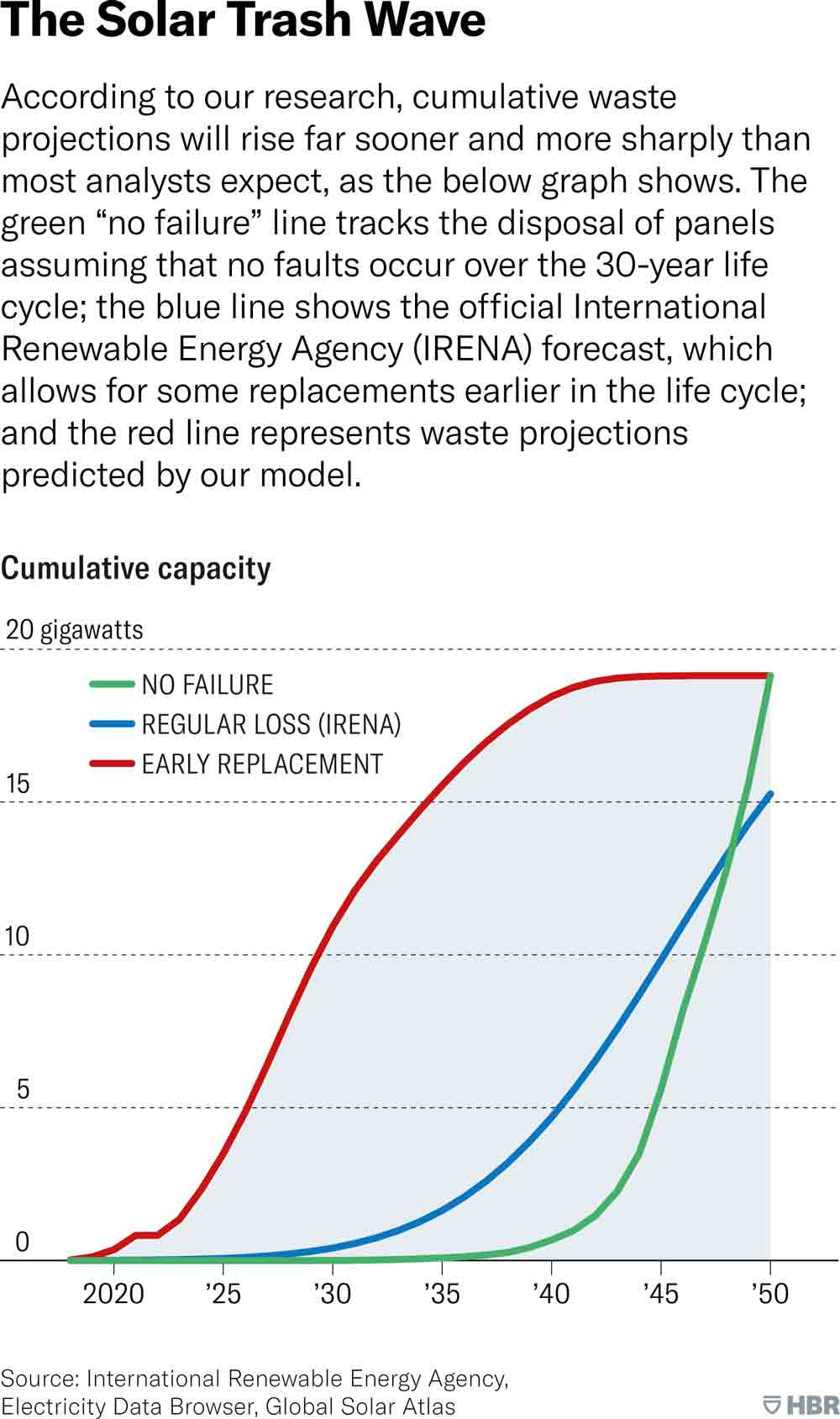

“Large amounts of annual waste are anticipated by the early 2030s” and could total 78 million tonnes by the year 2050. That’s a staggering amount, undoubtedly. But with so many years to prepare, it describes a billion-dollar opportunity for recapture of valuable materials rather than a dire threat. The threat is hidden by the fact that IRENA’s predictions are premised upon customers keeping their panels in place for the entirety of their 30-year life cycle. They do not account for the possibility of widespread early replacement. Our research does. Using real U.S. data, we modeled the incentives affecting consumers’ decisions whether to replace under various scenarios.

If early replacements occur as predicted by our statistical model, they can produce 50 times more waste in just four years than IRENA anticipates. That figure translates to around 315,000 metric tonnes of waste, based on an estimate of 90 tonnes per MW weight-to-power ratio.

Alarming as they are, these stats may not do full justice to the crisis, as our analysis is restricted to residential installations. With commercial and industrial panels added to the picture, the scale of replacements could be much, much larger.

The industry’s current circular capacity is woefully unprepared for the deluge of waste that is likely to come. The financial incentive to invest in recycling has never been very strong in solar. While panels contain small amounts of valuable materials such as silver, they are mostly made of glass, an extremely low-value material. The long life span of solar panels also serves to disincentivize innovation in this area.

As a result, solar’s production boom has left its recycling infrastructure in the dust. To give you some indication, First Solar is the sole U.S. panel manufacturer we know of with an up-and-running recycling initiative, which only applies to the company’s own products at a global capacity of two million panels per year. With the current capacity, it costs an estimated $20–$30 to recycle one panel. Sending that same panel to a landfill would cost a mere $1–$2.

The totality of these unforeseen costs could crush industry competitiveness. If we plot future installations according to a logistic growth curve capped at 700 GW by 2050 (NREL’s estimated ceiling for the U.S. residential market) alongside the early-replacement curve, we see the volume of waste surpassing that of new installations by the year 2031. By 2035, discarded panels would outweigh new units sold by 2.56 times. In turn, this would catapult the LCOE (levelized cost of energy, a measure of the overall cost of an energy-producing asset over its lifetime) to four times the current projection. The economics of solar — so bright-seeming from the vantage point of 2021 — would darken quickly as the industry sinks under the weight of its own trash.

The required solar panel recycling capacity has to be built, as part of a comprehensive end-of-life infrastructure also encompassing uninstallation, transportation, and (in the meantime) adequate storage facilities for solar waste. If even the most optimistic of our early-replacement forecasts are accurate, there may not be enough time for companies to accomplish this alone. Government subsidies are probably the only way to quickly develop capacity commensurate to the magnitude of the looming waste problem.

If you think “Wind” must be much better than this, see my other articles (below).

And has anyone asked what happens to these solar farms when the same governments handing out the “free money” start blocking the sun so the planet doesn’t “boil”?

If you do decide to use solar panels for your small off-grid purposes, I would suggest thinking about vertical installation:

It is counter-intuitive, but new research shows it can be more effective in capturing the sun year round and, most importantly, it won’t be affected by the weather as much.

It also takes up less valuable land. But think about what you do with the panels in 20+ years so they don’t just go into a landfill or contaminate our planet.

Governments should stop encouraging solar farms with “free money”.

Maybe we should all encourage fusion technology like this to meet our future expanding needs:

Helion’s fusion approach does not produce high level radioactive waste. Our machine does produce tritium. Tritium’s half-life is only 12.3 years (compared to 24,000 years for fission waste). As tritium decays, it turns into helium-3, which we use as our fusion fuel.

In addition to tritium, the radiation from fusion does create activated materials over the operating life of a power plant. Helion’s plants have been specifically designed to only use materials that would result in low levels of activation.

Helion’s fusion approach has no possibility of creating a chain reaction, and the machine shuts off instantly. There is no risk of a runaway chain reaction.

Helion’s fusion generators will produce a manageable amount of radiation while they run. Helion can use commercially available shielding materials (e.g., concrete) to limit the amount of radiation that leaves the vicinity of the machine.

Further reading:

Don’t Worry, Insurance Will Pay For More